Whether you call it a large purchase, a Cap-Ex, or just big money, a system for making large purchases in your business is a must. Use these tools to prevent costly mistakes on your next printer, cutter, or other large equipment purchase.

Scroll down for a transcript from the video!

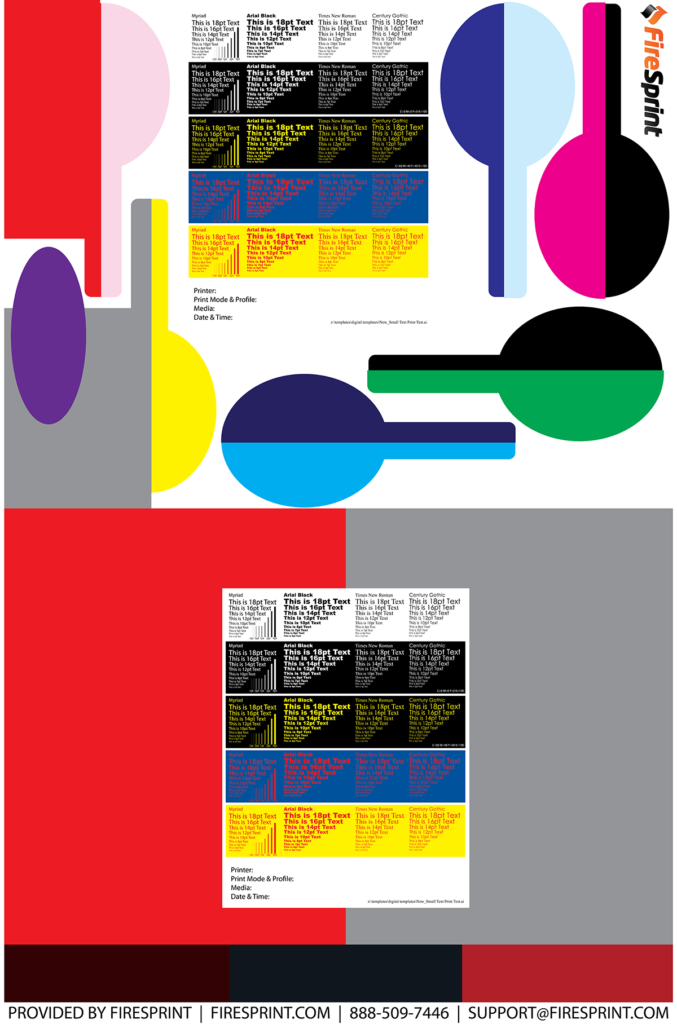

Check your overall print quality with this file full of small text and color blocks that are challenging for printers to print.

TRANSCRIPTION

Title: FireHour: How we justify equipment purchases at FireSprint

Date: 11/11/2021

Duration: 50:33

James: Hey guys, we’re back, thanks for joining us. I got Gene here and I’m James, we are two of the three owners of FireSprint, and today we are going to go over How we process buying equipment. So Gene’s got a little slideshow presentation that he’s going to go over, but it’s definitely a big challenge for us to figure out what printer to buy, how we do it and everything. And so we have a few things to share with you, like the presentation here. Then also the file that we use to send to other print manufacturers and stuff, which we will share where that’s at so you guys can download it for free and use that when you’re looking.

Gene: Some of you guys following know from our very first FireHour, we announced that we are in the process of trying to buy a building. And so what’s going on with that is there’s a due diligence period. So we made an offer, that offer was accepted by the sellers, everybody’s pretty happy about the price that we want to pay. But then we have 60 days to get all of our ducks in a row, make sure we have finance, and everything else. And then we can back out for any reason within those 60 days, according to the contract. Now this is all negotiated. Then after that 60 days, we must continue with the purchase of the building or we’d lose our deposit, which we have a $25,000 deposit on the building.

So it’s a pretty significant amount of money, but things are going really smoothly. We’ve gotten bids on all of the work that we need to do, and then we’ve also found out what we need to do about the fire sprinkler system. So the building we’re in right now does not have a fire sprinkler system, it’s old enough, it’s grandfathered in. And so this new building that we’re moving into has a fire sprinkler system, but we need to adjust it. And to keep this from getting too boring and a long story, we’re going to need to put in a whole brand new fire sprinkler system we’re finding out. But it is something that we’ve kind of accounted for in terms of the cost I think, and so we’re waiting on some bids back on that and hopefully we can move forward, but there’s just a lot.

If you guys are crazy and interested in that, feel free to get ahold of us. So you are welcome to email me with direct questions, which I’ll generally answer on the air here, [email protected]. And then of course, we’ve got James here, [email protected] just the same. So feel free to email us with questions if you’re watching this video not live. So let’s just jump into it for our process for purchasing equipment here.

So we’ve got smart equipment purchases for sign and print shops. And so we have bought a ton of equipment, we’ve bought a ton of equipment that we’re very, very happy with. We have also bought a fair amount of equipment that we’re not so happy with. And so this process that we’re going to take you through today, this might be a little bit longer live stream today than the last few or couple I guess. But we’re going to kind of deep dive into the steps that we take now to make sure that we’re making a smart equipment purchase.

[5:29] Do I Need a Process?

So do I need a process for purchasing equipment? A lot of times if you’re a small shop owner, it’s kind of a gut feeling and you might talk to some questions and you talk to some vendors. And you have a salesperson just bug you enough that eventually you commit and say yeah, I’m gonna buy that roll printer. Or yeah, I’m gonna buy that cutter, or I’ll buy that copy or whatever it is, but I think a defined process can be very useful. A defined process helps remove emotion, it slows things down, it answers more questions and it will improve the outcome, and ultimately that leads to you making better decisions. One of the keys here is to kind of slow things down and take the emotion out of the process, so really trying to make that equipment purchase a very pragmatic purchase. Something where the numbers line up and maybe your accountant would agree that you should be buying that equipment.

[6:39] Napkin Sketching Our Example: A New Roll Printer

I like to call this a napkin sketch, so the first thing to do with this whole process is to napkin sketch out your idea. So let’s say you want to buy a roll printer, maybe it’s a Roland, an HP, Mimaki, an Epson roll printer, or something like that. Let’s say that the HP latex role printer is at the top of your list, and that’s what you’re expecting to buy. So on a napkin literally, I mean very drafted, very broad, you want to start with the opportunity and define your opportunity. So that is what customers are going to buy from you, what are you going to sell; describe that in a big picture sense. Describe the requirements that this printer would have. So how fast does it need to be, things like that. Who will be involved, is it just you, are a one-man shop, one woman shop? Do you have one employee who’s going to run this printer? Who is going to be involved in the purchasing decisions, things like that.

And then you need to go out and gather as much information as you possibly can about these printers, and we’ll get deep into that and how we gather information about them. You need to understand the upfront costs, those are the kind of the one-time costs, the installation and the actual cost. In this example a printer, but it could be any piece of equipment, and then you need to understand the ongoing costs. So in the case of a printer, it could be ink, in the case of a cutter, it could be the blades. It’s maintenance costs, it’s maybe additional electricity costs that you need to factor in and things like that, but what are those costs. The output, so what is this machine actually going to give you that you’re going to sell, in this case, it’d be a printing product.

And then with that, you should be able to start to calculate an ROI, a return on investments, and then you want to look at the risk and opportunity costs, assuming everything else kind of lines up.

[8:42] Refine the Opportunity

So the first thing you do is refine the opportunity. If you’re thinking kind of big picture, if you’re thinking as an entrepreneur, if you’re thinking as a salesperson, obviously buying a printer without anybody’s selling even if it’s output to is probably not ideal, right? There’s gotta be somebody out there. So what is this opportunity? Why are you even interested in buying this thing in the first place? And so who are the new or existing customers that will benefit from this printer? What new products and services will you be able to add because you’re adding this piece of equipment? How much additional revenue and profit could this add to your business? And then why is it important to your business growth? So I think those first three are self-explanatory. I think that ‘why’ is important. Why requires a little bit of vision, and it’s how does this fit into your vision for growth. So if you think about your company two years, five years, ten years down the line, is this piece of equipment part of that vision, does it fit into that growth plan? So that’s something that you really need to refine as part of your opportunity.

Now if you’re following this exactly, we’ve started with kind of a napkin sketch, and so this is a deeper refinement of that opportunity. Your first sketch down on a napkin or a piece of paper might have just had a couple of points. And then when you go and do it again, you’ve gotten more detail with it. And I believe in making big decisions in that way. So you kind of think about the whole picture as a quick draft and you go through it as quickly as possible so you have an understanding of the big picture. And then you keep honing in on it, you keep circling back to it trying to get more and more detail. So in buying our building, one tiny part of it was we had a GC, a general contractor come out and look, and we gave him a list of everything we wanted to do. And then we went to the individual areas and we said okay, there is plumbing that needs to be done, so let’s actually have a plumber come in and really define what the plumbing bid is going to be. So we get this kind of big-picture idea of what needs to be done, and we think about that. Then you go back down and you start to refine that idea deeper and deeper.

[11:04] Refining the Requirements

So define what the requirements are for the successful execution of the opportunity. So what are the quality standards? What are the speed requirements? What kind of floor space do you need? Those kinds of things I think you’re probably thinking about already, especially if you’re buying a printer, you know, how fast is this thing going to be able to output? How fast does it need to output? Let’s say you have a customer that orders 224 by eighteens, and they need them next day, every time they order. And that’s the customer that’s on the top of your mind. Well, you have a speed requirement then that you have to be able to output that order along with any other orders that you have in the system fast enough to meet that customer’s requirement. And so obviously, a floor space, where are you going to put this thing.

And then the all-important, probably the most important quality, particularly in printing, but with any piece of equipment, there often isn’t a baseline quality standard. There is your perception of a quality standard because your customers have given you this perception of a quality standard that you must maintain. And so we can never really take our salesperson’s word at where our quality’s going to fit within the speed, we have to actually see it. But that quality standard is something that you want to define early on. What is required for that? And other things that you might not be thinking about particularly if it’s a printer, if we’re using that example, you know, is color gamut, what’s the color gamut requirement? Do you have customers with particular colors that you need to hit? Is there going to be an issue with a smell? Maybe you’re a two-person sign shop, but you work out of somebody’s garage and there’s a bedroom above that garage. So that smell that this printer or this equipment or the noise, or any sort of pollution that this thing might put off; noise, smell, or waste products that need to be taken care of. You need to consider that and define whether or not those things would become a make-or-break issue or a deal.

Environmental impact might be important to you. You may want to make sure that for example, prop 65 compliance, which is a California proposition. They have like 3000 different chemicals that can’t be within the cured inks. So do you need to make sure that the end product that you’re selling can be prop 65 compliance so that you can sell it wholesale to Etsy sellers or something like that? So that could be very important questions that you may want to ask. If you’re not in the United States, there are plenty of requirements in Europe and everywhere else that you may have to consider based on what you’re offering. If you sell to a lot of hospitals, they have a lot of fire code compliance things and stuff like that. So way beyond my scope and what I understand, I just know that these are questions you should be asking yourself.

And then ‘who’ will make the decision. It might be kind of silly, especially as you get into a larger organization, sometimes it’s not clear who’s going to make the final decision. Who has the final say on this? Is it a group of people, is it a partnership or is it a single person? But then deeper, who’s going to operate this machine day-to-day? If you’re a one-woman shop, are you going to operate this machine every day, or are you going to maintain this machine every day? Are you going to have somebody else do the maintenance who isn’t also the operator? We have some of that happen here at FireSprint where some of the maintenance isn’t necessarily done by all the operators. We might have two or three operators run in shifts in series, and we do the maintenance. You know, more of the bigger maintenance items once a day, so only one of the operators is doing that. And then who’s going to service it, do you have a local service technician? Do they have to fly someone in, how long is that going to take to get those service people in? So these are those considerations on who will accomplish that.

[15:10] Information Gathering

So I think at this point, now that you’ve kind of refined the opportunity that you have, and you’ve refined the requirements that this piece of equipment in our case of a printer is going to have, then you are in good shape to go out and start gathering more information. So when you contact your sales reps for these printers, and you have a list of requirements, it’s gonna be much easier for them to present you with their best foot forward. Rather than just going and say what do you have, you go to them and you say, I have this opportunity, and I have these requirements, do you have a piece of equipment that’s going to help me achieve my goals here? And so you go through the information gathering and generally what we would do is we would list all of the possible printers that we would be interested in buying. So all the possible solutions, list them out and then gather as much information as possible. And I’m going to go deeper into this here as we go along, but I like to think the first stage is kind of reading brochures. Nowadays it’s more like going and visiting the website of these guys and just kind of understanding and getting a really high-level overview.

Then the second step of information gathering is to request quotes, request more information, actually start that dialogue with your sales reps. Then the third step is qualifying, so what you’d actually do to prove that this machine is going to meet your opportunity and meet your requirements. And then finally negotiating and making that purchase and kind of establishing a price and all the other services that you may want to negotiate around that equipment.

[17:10] Info Gathering: Costs

We’re at cost now, so list and understand the cost. Do this for each possible solution. Fixed and semi-fixed costs like labor, rent, loan payments should be calculated by the month. So I get this question a lot, like how do I understand my cost? Well costs are generally over time, so your loan payment is a cost over time. So it’s a cost per day, it’s a cost per week, it’s a cost per month, but most of our bills are hitting us on a monthly cycle. Even payroll is generally like a twice a month thing. Here at FireSprint, it’s exactly twice a month. But it’s easier in my mind anyway, and you can break this down however you need to, but it’s easier in my mind if things are broken down by month. And so we need to understand that this equipment that we’re going to purchase is going to return on investment. It’s going to pay for itself every month, and that’s really the main focus or the main factor with that.

So back to the different types of costs and things you consider here. Of course, you have upfront costs and those upfront costs may include a purchase price, installation, shipping modification of the existing space, additional software tools, and additional computers. Every time we buy a piece of equipment it seems like we have to hire a carpenter because we’re moving walls and things like that to improve our workflow. So you need to try and consider those costs and at least the upfront costs of the setup. And I would take those upfront costs, any of those fixed costs, and I would generally extrapolate that, or I would break them out over the lifespan. So if you have $5,000 or $10,000 right up front on the cost of this machine for it to ship to you or something like that, and for you to rebuild the room. Well if this printer is going to last five years, I would take that $5,000 and figure it over about 60 months to ROI. And you might give yourself an interest rate or something like that. We could spend all day talking about that, but to keep things really simple, you’d extend it over the 60 months or five years.

And then of course ongoing costs, so consider labor, maintenance, ink, electricity floor space, service agreements. You know we are a big fan of service agreements, most of our big pieces of equipment have service agreements on them so we know what it’s going to cost to keep that maintained no matter what. Even if there’s a major failure with it, generally our costs per month are pretty fixed. And then consider the term length for those service agreements or the costs, and then that falls back into lifespan. So take all those costs that you’d have over the entire life of the machine, and then estimate how long you think that machine is going to give you a good…

James: Well I think you also need to add in cost. Like for example on our Zund, we have a belt that needs to be replaced roughly every six months, or a certain number of boards, or average boards over six months. And that’s not a cheap process, that’s a fairly expensive piece. I mean it’s 16, $1,800 to replace that belt. And then you’ve also got as you had said ink, but you have consumables, so if you have blades or any parts like that, that need to be replaced. Print heads on there, obviously you are going to average out replacing a print head X number of months, on average or something.

Gene: Yeah, I guess I don’t actually have consumables listed there, but yeah we are replacing the belts on our Zunds every six to 12 months. You have a print head fail probably once a year maybe on average across all machines, and that varies. But those costs are really important to understand and then spread them out the best you can over that longer period of time.

[22:12] Info Gathering: Output

So output, and this slide here is the one that you guys all joined this live stream to understand. I think the other stuff is really important, but when you think about how to pick a piece of equipment, I think you kind of go to this thought process right here, and you skip all that other stuff. Which you should not, but this is where it’s at. So use real-life qualifications whenever possible to clearly understand the output of the equipment. So the first thing, and I use the word brochures, but request samples from these guys, get on the website, do as much research as you can. Get on Signs101, get on SIGN SHOP TALK and ask other people, “Hey, I’m interested in this machine.” By this point, you’ve qualified down and you have a few machines that you might be looking at. I’m interested in this piece of equipment, does anybody else have any experience with it? A lot of times you’ll get some feedback that way, just some basic stuff. And then that’s kind of the first three points there (brochures, request samples, talk to owners).

Request those samples from the manufacturers themselves, they should be able to provide you with samples that they have just sitting on a shelf somewhere and give you an idea of what you’re looking at. When you’re looking at a printer, requesting the samples gives you a good idea of sheen. It may give you a fair idea of ink adhesion and durability based on the material that they say that that sample is on. It gives you some understanding of what to expect in a perfect environment. Now, keep in mind that the samples that these suppliers are going to send you should be perfect. And if they can’t get them perfect in a production environment, it’s probably not gonna happen. So keep that in mind if they send you stuff that isn’t perfect.

Then really reach out to other owners. Personally, this community has been incredibly helpful. When we have questions, there are owners from all over the world that’ll chime in and say “Gene have you tried this? Have you done that?” And being on Signs101, I think James is on SIGN SHOP TALK a lot, but usually people are very helpful. It’s a very hobbyist kind of culture, a lot of makers, a lot of self-starters and small shops, small entrepreneurs. So it’s usually pretty easy to get some information, especially about these printers that we’re talking about here and get some feedback on it. And then what you really want to do is you want to see it in person the best you can.

So what we do at FireSprint when we are qualifying a printer for example, if they have a showroom or something like that, we’ll send our own material there. And let me elaborate on that real quick. So you think about this printer, this might be a $25,000 printer, and you’re going to run 250 rolls of vinyl through it. And so you’re thinking to yourself okay, well the printer’s important, I got this printer. But if you do the math and you actually run these things, for us anyway, whatever we spend on the printer, we have a half- million-dollar printer out there, we spend far more money on materials than we do on the printers. And so between material and ink, they end up being the biggest cost. For you, it may not necessarily be ink, but it doesn’t take much to get to a point where you’re spending more money on the material than you are on the printer.

I think one of the biggest mistakes that we have made in the past and that I see being made is that you think it’s all about the printer, but it’s really not. It’s about how the printer interacts with material that you guys want to print on and that you want to use. So buy the material from your vendor and send it off ahead of time to the showroom and make sure it’s there. And we’ve done that many times, we’ve sent whole pallets of material or at least your most popular few and then send your own files. And we do have a sample file, which we’re going to get you a link down in that description to the blog post, which will link to the sample file. So James, talk about our sample file, what do they print at the trade shows?

James: Absolutely. So what we do, if you walk around any of the trade shows, you will see pictures of giant scenes and everything like that. Like beaches, people, models, scenes, just all sorts of different things. Things with lots of different colors, lots of skin tones and stuff like that, there’s a lot of breakup of colors. But we’re a sign printer, and so what we print the most of is blocks of reds, blocks of grays, blocks of blacks, blocks of blues and stuff, which no printer likes any of that stuff. Because it shows every single little default or defects you possibly can. If you have a nozzle out, it’ll show bending like crazy.

Gene: It is interesting. What you really should see at the trade show, the most impressive thing that they could be running off the end of their printer at a trade show is just a giant rectangle light gray, And say look at how consistent this like gray is, but they don’t do that.

James: But yeah, it’s kind of cool, and we’ll share this test file with you guys so that you can use this. It goes from small text to large text and then all sorts of different colors and stuff, and then you can also see kind of just how things look. But we’ll share that with you guys so you have access and you can use it on your own when you’re testing out equipment. One thing that I wanted to also touch on was when you go to send your test files and you go to send the material and stuff there, verify that everything is actually right. You know there’s been times where we’ve tried hard to run tests and stuff like that. And I mean you see that something looks 100% perfect, and then you find out that something wasn’t quite right on the settings, and so do it 2, 3, 4 times. And then I think another thing that we should also touch on is when we were buying our Durst P10 250, just the amount of due diligence that we did when we bought that piece of equipment. It’s a big printer and it was scary for us, and I think we traveled to like 14 or 15 different countries.

Gene: Something like that, we were all over the country looking at printers.

James: Yeah and just running everything. And we went to demo facilities, we went to other shops and stuff and saw it all. But it really kind of exposes what a printer is capable of doing. It kind of helps you figure who you want to hit your wagon to and who you want to run with and stuff, and so that due diligence. Then another thing I wanted to touch on too was we were talking about ink costs and stuff like that. And I remember when we bought our Durst P10, 250, we were negotiating between EFI and Durst. We were negotiating costs per liter versus the cost of the machine. So if we wanted to drop the cost of the machine, they would raise the ink cost, and if we wanted to lower the ink cost, we would drop the… And when we were buying that printer, it was a bigger printer than what we needed. We were definitely stretching our limits a little bit by purchasing that piece of equipment, which thankfully worked out and we ran it. But when we bought that we wanted a lower payment so that we could make the payment, and we weren’t quite as worried about the throughput of it. But I remember talking to a couple of other larger shops than us and they were talking about how the payment obviously wasn’t as big of an issue for them at that point.

Gene: Yeah, I’ve heard rumors that some of these massive shops will hardly pay anything for the printer, because it’s all in the ink, they use thousands of liters of ink like a week. And so just to get things rolling, we have never been made that offer, but it makes sense to me because the ink is really where it’s at; it’s that ongoing price. So we have seen where you could wrap 10, 20, maybe 30% of the cost of that machine into the cost of ink. And then that’s great too because if you’re going through a lot of ink, your sales are up, it’s a little easier to swallow that ink payment than it is just a hard payment to the leasing company or the bank every month. So that’s a really good point.

Back to seeing this in person, and dare I say it this way, but kind of the cool thing about the pandemic that we’ve been dealing with here is that people have gotten really good at setting up cameras and doing stuff like this and live streaming. We’ve been doing more and more demos with equipment just over the internet. We’ll set up a time tomorrow at noon, we’re all going to get together and they’ll put one or two cameras in their facility. And they’ll have an operator there and we’re directing that operator, okay can we load this file? And then he’ll walk the camera over and he’ll show it real close. And then they ship us all those samples back after the fact so we can actually see them ourselves, but they basically become our eyes and ears and hands without us needing to travel. So when we bought our first Durst, we spent $30,000 in travel and we had a good time with it, but it was expensive. And so you don’t necessarily need to do that anymore, you can really get in there. But have them print your file and have them print a known variable, and you do this across all of them, don’t just let them print whatever they want, give them your file. So you give every company your file and then stopwatch it, clock it yourself and understand that cost.

What we’ll generally do is we’ll walk in with our clock on our phone and we will start the timer at the highest speed. We’ll run that and we’ll see how fast it can print, like on a rigid board printer or something like that, and we’ll see how fast it can print a 4 by 8 sheet with our own clock. So whether we start the timer when they hit print or when we start the timer when the carriage starts moving or something like that, the important thing is we keep that consistent. I like to start it when they hit print because the time it takes to move that data into the printer is time that your operator is just standing there. But whatever you do, keep it consistent, time that, and time it at the fastest speed. And then you’re going to look at that quality and chances are real good that that quality is not going to be acceptable for you. We’ll then go one or two steps up and time that one and see how fast that one goes and see if that quality is acceptable for you. And when you kind of find that acceptable quality, you already have that speed time, now you can try a few different test files at that point. And you’ve got a really good idea of what your consistent output is going to be.

Now a lot of the smaller shops out there I think speed is not so critical like it is to us. We sell time on our machines. Everything we did, we figured out how long it’s going to take, and then we understood what our costs are per hour, and we did it that way. Everything on our website is like that, it’s all based on time. It’s not really based on a multiplier or times the cost of material or anything like that. The finite resource that we have is time on our equipment. But even in your case, you have that customer, that’s like I need 200 of these signs by tomorrow. Well you have to understand how long that’s going to take, and it’s good to understand that before you buy that equipment. The way to do that is to actually take your stopwatch app on your phone in with you, with a known file. Which we’ll give you our file and you can modify it, do whatever you like.

James: Also we always time 10 boards.

Gene: That’s a really good point. Yeah, we’ll run 10 boards, it’s not just one print, but it’s 10 boards because if you hit the print button, that first word might take 20 seconds to start running. But then the time between boards might be a lot lower or it might be a lot higher than we’re anticipating. So that time 10 boards, if you’re doing long runs, it gives you a good understanding of what your output per hour is going to be. And then you can multiply that out by the month and figure out if you have ROI.

[34:48] Calculating the Return on Investment (ROI)

So what is ROI? I could talk for three hours, I know I’m long-winded anyway, but I talk for three hours about ROI and how to calculate it. At its core, it’s pretty simple to calculate. You’ve got the additional revenue that you’re gonna bring in, so how much you’re going to sell these signs for that you’re going to sell or whatever it is. Then you’ve got hard costs per month and you’ve got your input costs and you take those out of that, and we would call that gross margin. And this goes back to the month. So just quickly touching on this, when we were a smaller shop buying equipment, and we talked about this a little bit before, I’m going to sell three or four boards a day. I’m going to make $50 a board net after my hard costs and my input costs so that’s $200 a day leftover after material cost and things like that. And then I’m going to be able to do that three days a week, just being realistic about this. So that’s $600 a week, call it four weeks a month, that’s $2,400 a month. Well if I have a $300 printer payment or something like that that might be a good ROI.

None of us can tell you what a good ROI is for you, where the risk comes in, that’s a little bit where the entrepreneurial spirit will tell you if that’s worth it or not. But that basic calculation needs to make sense though, you need to really search your soul. And what do you think realistically you’re going to sell by buying this equipment and how much you’re going to make off of that. And whether that nut is worth the additional risk that you’re taking on to put this piece of equipment in place.

[37:17] Understanding the Risks

Speaking of additional risks, after you’ve kind of done all this and some of you guys might see this as backward, I’m not I would say risk-averse when it comes to taking risks on buying equipment and things like that, so I do the risks last. In some respect, by doing the risks last, you understand the most that you will by doing all the other processing first. You get to the risks, and at this point then, your understanding of the risk should be the clearest. If you just start with them, first of all, you might kill a great idea too soon, but secondly, the clarity may not be there. So I intentionally leave these at the very end of this thing or near the end, I still have one more for you, but what are all the possible risks associated with this purchase? Then rate those risks on a scale of not likely to most likely. And consider your response to those risks if they were to happen, (what’s your plan B?).

So obvious risks, you’re not going to make the payment, so what are other risks in buying equipment? Like it doesn’t do what you wanted it to do, the thing just quits. It stops working or the output just isn’t quite what you expected. You were expecting to be able to print a roll every couple of hours and it takes you two days to run a full roll. And you thought that you’d be able to run it overnight totally unattended, but that didn’t work out for some reason.

So head crashes, you may have a service agreement on a printer, but if you have a head crash the service agreement may not cover that. So you have this additional risk where now suddenly even on our smaller printers, if we have to replace all the heads, we very quickly get to the original purchase price of the printer. A lot of times the cost of replacing the heads and putting that in, you’re there, so there are those risks. And so those are kind of the obvious ones and you really should write them down somewhere and understand them. Then there are the opposite risks, and these are the things that I think people who are very risk-adverse don’t think about, but there are risks to not investing in your business.

James: Yeah, there’s been plenty of times where we personally have looked at buying a piece of equipment or something or not necessarily just equipment, but we’ve looked at expanding and taking on more space. We have 16,500 square feet where we’re at now, but that’s segmented over three different shops, we turned it into three different bays. We had lots of conversations, like do we really need to do this? Our conversation always came back to if we don’t take this bay over, then somebody else could move there and then we can’t take that space. And now we are truly landlocked. We’ve got somebody in a three-year lease to the north of us, and we’ve got a brick wall on the south of us.

Gene: Are your quality standards right now not high enough and investing in new equipment, going to raise that quality standard. And if you don’t do that, you may potentially lose some of your largest customers. I would say a lot of times the risks of not growing have a lot to do with losing people. Either losing your employees, your team, because people want to be part of a growing organization. Or if your customers aren’t seeing new products and new opportunities to work with you, continuous advancements in quality, speed, and lowering price. If you’re not making those investments, you risk losing people. Sometimes those risks, when you start to weigh them all out, it’s actually kind of balance where it’s like well, it’s not really not risky to not invest in the business. That can be very risky too, to not make those investments.

[41:50] Opportunity Cost

Opportunity cost. This is one of those costs and I kind of purposely left it at the end here, but what is the opportunity cost of buying a piece of equipment? And this kind of rolls into risks or rolls out of risks. But in my opinion, I think it’s oftentimes one of the most overlooked costs, but it is very real in a business. You have a finite amount of money and resources and time, and so that opportunity cost is something that you have to constantly consider. Oftentimes we look at these decisions as being well should I do it, or should I not do it? Well that’s not usually how a decision works in business, it’s usually a decision of should I do this or should I do that? And if there isn’t an or, like should I buy a printer or not, if that’s what you’re thinking, if the or is or not, then there’s probably something that you’re missing. There is almost always should I buy a printer or should I hire a salesperson or should I hire a production person, or should I buy a truck to do better installs or whatever. There are a lot of things. I mean, most of the printers we look at cost as much as a vehicle.

So what else could you have purchased instead? And then of course there’s a time opportunity cost. We’ll focus on production, take away from customer service or something else. So I know there’s a ton of people that are going to hopefully get to this point in the video and you are at that spot, if you’re a one person shop and you don’t own any equipment. And you are spending eight hours a day doing design installs and working with your customers, consider buying a printer. Now you’ve got a half-hour of maintenance every single day, and you are not doing anything for your customers during that period of time. So if you have a production person, they’re already in the shop, keeping this stuff and it’s going to help. It’s a whole other thing if you’re going to take somebody off of a customer service role or a customer interactive role and put them back on a production floor, there’s a real opportunity cost to that. That’s one fewer customer that they’re going to interact with over whatever period of time. So it’s something very serious to consider.

Will the capital tied up in this equipment prevent you from reaching another goal? So that again is kind of where I said it’s really not a buy this or not. If you’re going to buy this, you’re going to extend your credit, and you’re going to have this monthly payment that you’re making. Maybe instead of buying a printer, maybe you should be buying a laser engraver, or maybe you should be again, getting a truck or something like that. So you can provide something that’s a little more unique.

Then kind of along those same lines, that same vein, floor space. Obviously you can’t put a piece of equipment in that floor space, but right now with supply chain issues, you also can’t put a pallet of material in that spot where this roll printer is sitting for example. So are you going to miss out on a sale like both a sale from your vendor at a lower price, but a sale as in selling that product to a customer because you just don’t have that material available because now you have less floor space to store that material? So that’s a real opportunity cost that you need to consider here. And then of course getting all this, basically what I’m saying is that we’re buying this equipment pigeonholed.

And so as soon as you buy a piece of equipment, as soon as you have this expensive monthly payment that you’re making every month that you’re thinking about, now suddenly you’re a production shop. You’ve kind of just a tiny little bit of focus on a customer maybe, and if that’s the case be careful with that. And so is it possible that maybe you can outsource this product? Whether it’s print or something else. And so if you can do that and that still use a similar ROI to what you calculated up above or up earlier, then maybe you should consider continuing to outsource. But that’s a decision that only you can make. It’s a decision that you have to make as an entrepreneur or as a department head or something like that. And if you are interested in outsourcing, firesprint.com.

James: There is one other thing too, and kind of tell you a quick story. So we have a customer that we have been working with for quite a long time. And I won’t say who it is or anything like that, all that is very important to us. But it was cool because they were growing, growing, growing with us. And I remember they actually were debating as to whether or not to purchase a flatbed and they were outsourcing work to us and a really good relationship back and forth and stuff. And I remember when we had the conversation about them talking about it and them asking us for advice and stuff. We tried to be as transparent as we could that if you can do it, you can bring it in, you can justify it. That’s awesome, that’s fantastic.

What’s cool about situations like that is if you’re a shop that’s growing and you’re moving in a positive direction, you do outsource a lot of stuff. And then you’re looking at bringing some equipment in and it might be lighter duty equipment than what your standard runs might be. You might try to focus on just printing smaller jobs, you know, one piece orders, 10 piece orders, 20 piece orders and stuff. And then it takes your production more than an hour to produce it. So you say well, that’s not really our focus, let’s drive that to one of our trade suppliers rather than try to produce that in-house. So then it allows them to focus on the smaller jobs while outsourcing the bigger jobs, and it really kind of becomes this good combination of synergy. And when your clients come in, they walk into your shop and they say “How are you producing this?” It’s like well, I got this printer right here. Even though that printer can do seven boards an hour or whatever, but you can at least still show the process. You can bring them in and you can show them samples. You can show them what it looks like, how it’s made. That’s really cool, and that gives a lot of confidence.

Gene: I would say 8 out of 10 of our biggest 50 customers run their own production, so many of them run their own production. And it might be something entirely different from us, it might be something that parallels what we do. But most of our biggest customers do run their own production. So don’t think that with the opportunity cost and what we’re talking about, that you shouldn’t be investing in your own equipment. You really should, but just make sure it’s the right moment, and you’re offering the right thing. Maybe it is something a little more specialized that you need to be offering. And we’re not the only trade printer, there are wonderful outsource partners in this industry. We have some really tough competitors.

James: Well you can sell a billion products, anything with a logo is at your fingertips with suppliers.

Gene: Does it make sense a lot of times to bring a little bit of your own production in-house either way. So maybe if that’s our last takeaway of this, if you’re like right on the edge and you’ve been thinking about buying something for the past like three months, do it. We got your back for everything else.

James: Well thanks for joining us guys, sorry it took a little bit longer than usual, but I hope you all learned something. And if you have any questions, please feel free, we dropped both my email and Gene’s email on there. And then you can also call us at any point in time to our 885097446, and let us know what questions you have. We will be monitoring the comments and stuff until next week, and if there is anything, we’ll do our best to answer it, or maybe even do a whole show about something that you guys bring up. So thanks for joining us.

Gene: Next week, we are going to be talking about marketing free things that you can do to market your business. Basically really simple stuff that we have that won’t cost you a dime, so don’t miss it. Thanks.